Guinea Waste Incinerator Market Report (2026 Outlook) — Focus on Conakry, Boké, Kankan, Kindia, Labé, Nzérékoré

1) Why Guinea’s incineration demand is rising now

Guinea’s waste treatment market is being pulled in three directions at once:

-

Fast-growing urban pressure in Conakry: municipal collection and disposal constraints typically translate into overflow at transfer points, informal dumping, blocked drainage, and localized flooding risks—patterns widely documented across African cities where collection rates are often around “half” on average.

-

A mining-and-port corridor that generates “non-typical” waste streams: Boké and Kamsar sit at the center of Guinea’s bauxite value chain, with heavy logistics and industrial activity that intensifies demand for controlled waste destruction (oily solids, contaminated packaging, workshop waste, camp waste). Guinea’s bauxite exports hit record levels in 2025 and are still rising, meaning more throughput, more camps, more service waste. (Reuters)

-

Healthcare and laboratory waste needs: medical waste management standards and implementation gaps remain a recurring challenge in many low- and middle-income settings, and WHO continues to emphasize the need for safer segregation and treatment pathways.

In practice, Guinea buyers (municipal contractors in Conakry, hospital managers in Kindia and Kankan, site operators around Boké/Kamsar, and NGOs working near Nzérékoré) increasingly look for reliable, quickly deployable incineration rather than long construction projects.

2) Market characteristics in Guinea (what buyers actually prioritize)

A. “Deployment speed” beats “perfect infrastructure.”

In Guinea, a solution that can be installed with minimal civil works is often favored—especially outside Conakry (e.g., Labé, Kankan, Nzérékoré). This is why containerized/mobile formats are gaining attention: they reduce site uncertainty and shorten commissioning time.

B. Mixed waste reality (not clean, not consistent).

Even when projects are labeled “MSW,” the real feed often includes plastics, wet organics, contaminated packaging, and occasional healthcare-related items. That variability pushes demand for:

-

stable combustion,

-

secondary burnout,

-

and (in sensitive areas) flue-gas treatment options.

C. A “compliance narrative” matters—especially when donors are present.

When UN agencies, international NGOs, or donor-backed projects are involved, documentation, training, and monitoring expectations rise (even if local enforcement is uneven). This affects specifications (secondary chamber temperature/residence time targets, operator safety, maintenance plans).

3) High-potential demand segments (Guinea-specific scenarios)

Segment 1 — Conakry municipal and peri-urban waste pressure

Conakry concentrates population, commerce, and public services, so the waste challenge is visible and political. Studies focusing on governance and municipal waste in Conakry describe consequences such as blocked drainage and flooding impacts from poor waste handling.

Incineration fit (when properly scoped): priority destruction of selected combustible fractions, “nuisance” waste at controlled points, and institutional waste (markets, compounds, secured facilities).

Segment 2 — Boké & Kamsar mining/port operations

Guinea’s mining expansion is not theoretical. Reuters reporting in 2025 showed record bauxite shipments and continued growth despite seasonal disruption. (Reuters)

Mining activity also brings well-documented environmental and social pressures (dust, land degradation, water impacts), reinforcing stakeholder demand for better site housekeeping and controlled waste management around Boké.

Incineration fit: camp waste, workshop waste, controlled destruction of contaminated combustibles, and emergency response capability during outbreaks or incidents.

Segment 3 — Hospitals, labs, and public health networks (Kindia, Kankan, Nzérékoré)

WHO highlights that unsafe healthcare waste practices elevate infection and injury risks and stresses structured management systems.

Guinea’s health/environment profiles also flag data gaps and uneven service readiness, which typically translates into pragmatic procurement: robust equipment + simple SOPs + operator training.

Incineration fit: medical waste streams (non-PVC infectious waste, sharps containers where allowed, contaminated packaging), with clear segregation and ash handling.

4) Role of the United Nations and international actors in Guinea’s waste market

In Guinea, UN agencies often shape “how projects buy,” not just “what they buy.” Key impacts include:

-

Funding logic: emphasis on deployable infrastructure and measurable outcomes.

-

Technical framing: risk reduction (public health), climate resilience, and governance improvements—areas where UNDP has active programming in Guinea. (UNDP)

-

Procurement discipline: specification clarity, documentation, spares, training, and after-sales support become decisive differentiators.

This is particularly relevant in Conakry (policy visibility) and in forest-region or border-adjacent operational contexts closer to Nzérékoré (public health and resilience priorities).

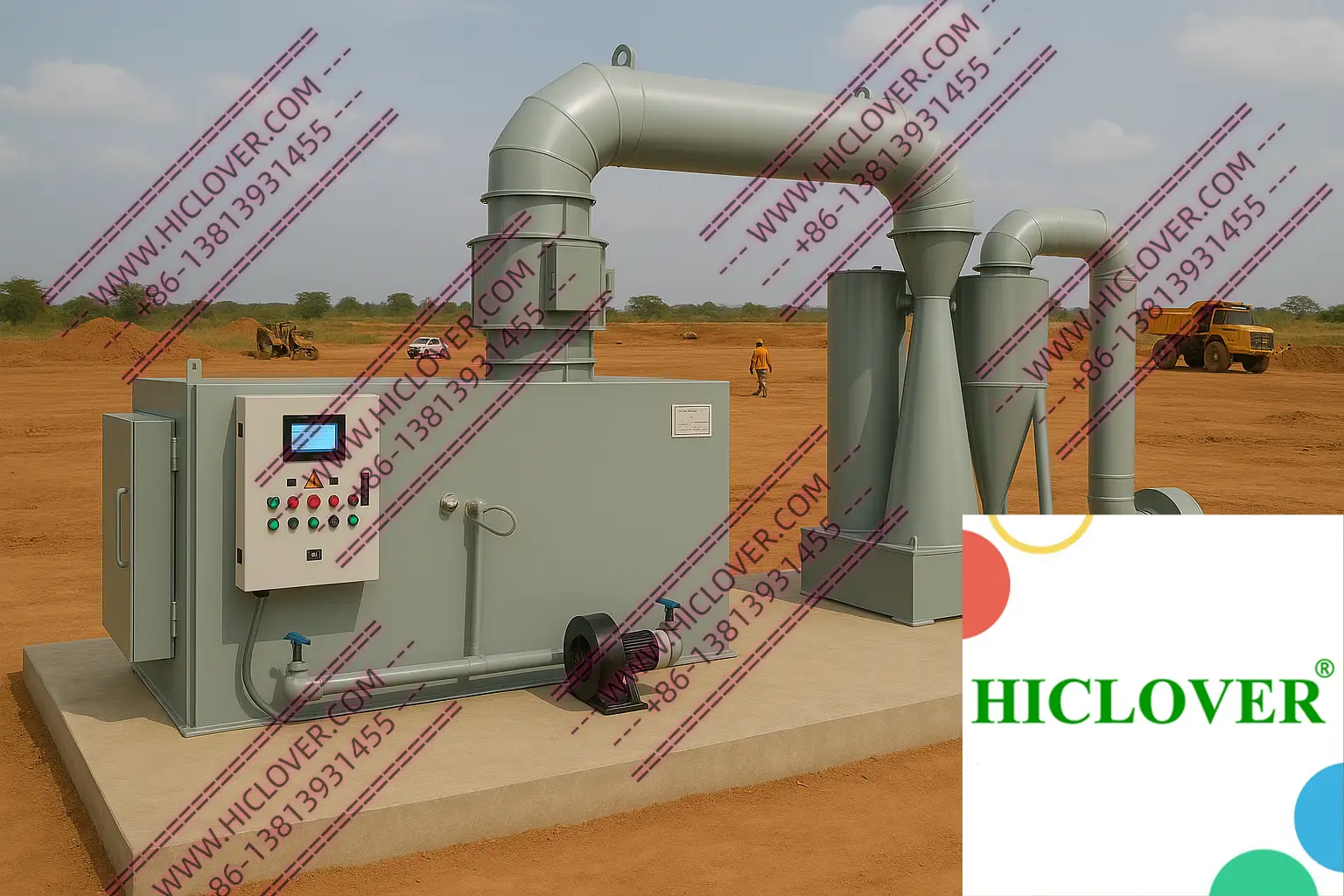

5) Product-market fit: why HICLOVER aligns well with Guinea’s needs

For Guinea buyers, the most credible value proposition is “durable combustion + flexible deployment + scalable gas cleaning.” That maps well to HICLOVER’s portfolio:

-

Containerized / mobile concept for rapid rollout and controlled installation quality

Explore: Containerized Mobile Incinerators -

Top-loading designs that handle mixed, bulky waste without complex feeding infrastructure

See: HICLOVER TS100 Top-Loading Incinerator -

Healthcare waste incineration options sized for hospitals and regional facilities (useful for Kindia/Kankan/Nzérékoré networks)

Example: Medical Waste Incinerator 30–40 kg/hour -

Optional wet scrubber systems for projects with higher sensitivity (donor sites, dense areas of Conakry, regulated industrial zones)

Reference: Incinerator with Wet Scrubber System

Practical advantage in Guinea: these configurations support both (1) semi-permanent installations near Conakry and (2) mobile/remote deployments in Boké, Kamsar, Labé, Kankan, and Nzérékoré where site conditions vary.

6) Trends to watch in 2026 (Guinea)

-

Industrial policy and “local processing” pressure in mining may increase construction of new facilities and camps—raising demand for standardized waste destruction packages around Boké and ports like Kamsar. (Reuters)

-

Higher scrutiny on environmental monitoring in industrial zones (refineries, logistics) will push more tenders to require clearer emissions-control options.

-

Municipal-private operator models in Conakry will keep expanding; they tend to favor equipment that is maintainable, not “fragile-high-tech.”

7) Recommended positioning (theme focus): “Mining corridor & port-city waste control”

A strong Guinea-facing message is to anchor around the Boké–Kamsar industrial corridor plus Conakry institutional demand:

-

Conakry: priority institutional waste and controlled destruction at secured sites

-

Boké / Kamsar: industrial camps + port logistics waste + emergency response

-

Kankan / Kindia / Labé / Nzérékoré: hospital networks and regional public services

This positioning sounds local, realistic, and procurement-friendly.

Résumé en français (très bref)

En Guinée, la demande d’incinérateurs progresse surtout à Conakry (pression urbaine), dans le corridor minier Boké–Kamsar (activité industrielle et camps), et dans les villes régionales comme Kankan, Kindia, Labé et Nzérékoré (déchets hospitaliers et services publics). Les projets soutenus par des acteurs internationaux (ONU/ONG) valorisent les solutions robustes, rapidement déployables (containerisées/mobiles) et, lorsque nécessaire, avec traitement des fumées. HICLOVER peut se positionner avec des incinérateurs top-loading, des solutions containerisées, et des options de wet scrubber adaptées aux contextes guinéens.

2025-12-13/18:00:22

|

Incinerator Items/Model |

HICLOVER TS100(PLC)

|

|

Burn Rate (Average) |

100kg/hour |

|

Feed Capacity(Average) |

150kg/feeding |

|

Control Mode |

PLC Automatic |

|

Intelligent Sensor |

Continuously Feeding with Worker Protection |

|

High Temperature Retention(HTR) |

Yes (Adjustable) |

|

Intelligent Save Fuel Function |

Yes |

|

Primary Combustion Chamber |

1200Liters(1.2m3) |

|

Internal Dimensions |

120x100x100cm |

|

Secondary Chamber |

600L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Manual |

|

Burner Type |

Italy Brand |

|

Temperature Monitor |

Yes |

|

Temperature Thermometer |

Corundum Probe Tube, 1400℃Rate. |

|

Temperature Protection |

Yes |

|

Automatic Cooling |

Yes |

|

Automatic False Alarm |

Yes |

|

Automatic Protection Operator(APO) |

Yes |

|

Time Setting |

Yes |

|

Progress Display Bar |

3.7 in” LCD Screen |

|

Oil Tank |

200L |

|

Chimney Type |

Stainless Steel 304 |

|

1st. Chamber Temperature |

800℃–1000℃ |

|

2nd. Chamber Temperature |

1000℃-1300℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

7000kg |

|

External Dimensions |

270x170x190cm(Incinerator Main Body) |

|

Burner operation |

Automatic On/Off |

|

Dry Scrubber |

Optional |

|

Wet Scrubber |

Optional |

|

Top Loading Door |

Optional |

|

Asbestos Mercury Material |

None |

|

Heat Heart Technology(HHT) |

Optional |

|

Dual Fuel Type(Oil&Gas) |

Optional |

|

Dual Control Mode(Manual/Automatic) |

Optional |

|

Temperature Record |

Optional |

|

Enhanced Temperature Thermometer |

Optional |

|

Incinerator Operator PPE Kits |

Optional |

|

Backup Spare Parts Kits |

Optional |

|

Mobile Type |

Optional:Containerized/Trailer/Sledge Optional |