Top-Loading Incineration for Modern Waste Management: The Strength of the HICLOVER TS20

The HICLOVER TS20 top-loading incinerator is engineered for organizations that need a compact, dependable waste-treatment unit capable of handling diverse waste without complex installation. What makes this model stand out is its top open door design, optimized for simple vertical loading, safer operations, and reliable combustion performance. This makes the TS20 a practical solution for medical facilities, farms, laboratories, humanitarian missions, and mobile field operations.

1. The Functional Logic Behind the Top-Loading System

A top-loading incinerator operates on a straightforward principle: let gravity assist the loading process. Opening from the top reduces direct contact with waste, minimizes heat exposure, and allows operators to drop materials directly into the combustion chamber.

The top open door provides clear advantages:

-

Better handling of mixed, irregular, or lightweight waste

-

Reduced operator effort with gravity-assisted loading

-

Less heat release when the lid opens

-

A simpler workflow for daily waste cycles

-

Higher safety in tight or improvised operating spaces

This design is especially effective where manpower is limited or where users require an intuitive system.

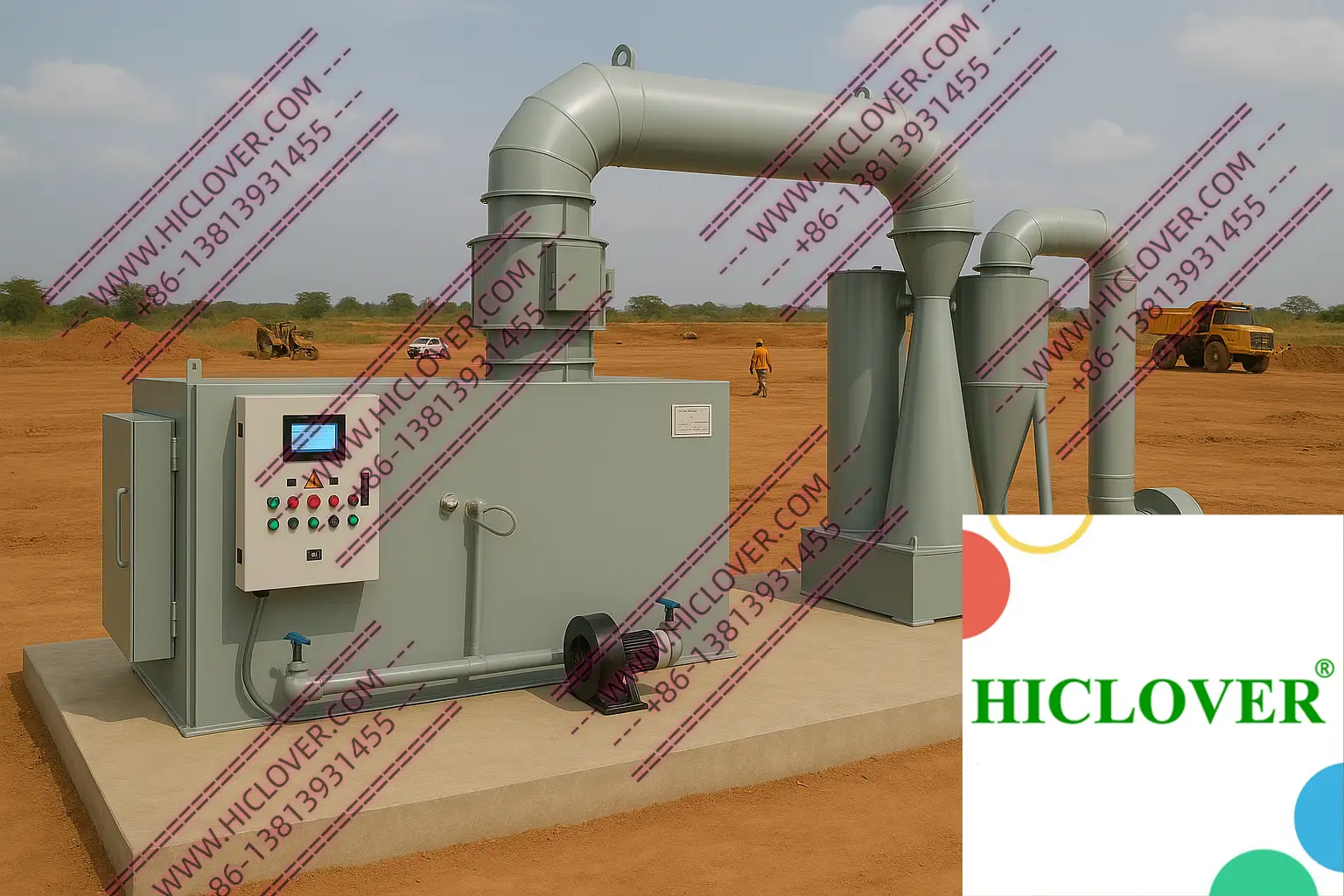

2. HICLOVER TS20: A Compact Model with Professional Performance

Although smaller than industrial units, the TS20 incorporates the same professional combustion structure found across the HICLOVER product line.

Key features include:

-

A reinforced primary chamber suitable for daily waste volumes

-

A secondary chamber for complete gas re-burning to reduce smoke

-

Digital or PLC-based controls with precise burner management

-

Reliable burners supporting diesel, LPG, or natural gas

-

Durable refractory materials built for continuous high-temperature operation

These engineering choices ensure that the TS20 provides stable, repeatable performance across various environments.

3. Mobile and Semi-Mobile Deployment Options

The TS20 is widely selected for mobile waste-management operations thanks to its light but durable structure.

Available configurations include:

-

Trailer-mounted unit for veterinary services, rural health teams, and inspection groups

-

Containerized system with ventilation, safety features, and easy transportation

-

Skid-mounted structure for industrial zones, mining camps, and temporary shelters

-

Rapid-deployment field version for emergency missions and humanitarian programs

The top-loading feature enhances usability across all mobile scenarios because vertical access is easier in uneven or restricted spaces.

4. Sector-Specific Applications

Healthcare Facilities

Small hospitals, health posts, and isolation units use the TS20 for infectious waste, PPE, paper waste, and contaminated disposables, especially in regions without centralized treatment systems.

Veterinary and Poultry Operations

The top open door makes it simple to load animal remains, poultry waste, and by-products, reducing handling risks and improving hygiene.

Research Laboratories

Laboratories choose the TS20 for biological sample destruction and safe treatment of contaminated light waste.

Humanitarian and Military Camps

Its mobility and minimal installation requirements make it suitable for remote sites, UN mission support bases, and emergency-response settings.

Commercial and Small Industrial Operations

Shops, workshops, resorts, and small production sites benefit from daily disposal of paper waste and packaging materials, reducing waste accumulation.

5. Why the TS20 Leads in the Top-Loading Category

The model remains a high-demand solution worldwide because it offers:

-

Straightforward operation

-

Stable, efficient combustion

-

Meaningful fuel savings

-

High compatibility with mobile platforms

-

Low installation requirements

-

Durability for long-term projects

The HICLOVER TS20 meets the needs of organizations that require a practical, cost-effective, and reliable waste-treatment unit with a top-loading advantage.

2025-11-24/11:30:55

|

Incinerator Items/Model |

HICLOVER TS100(PLC)

|

|

Burn Rate (Average) |

100kg/hour |

|

Feed Capacity(Average) |

150kg/feeding |

|

Control Mode |

PLC Automatic |

|

Intelligent Sensor |

Continuously Feeding with Worker Protection |

|

High Temperature Retention(HTR) |

Yes (Adjustable) |

|

Intelligent Save Fuel Function |

Yes |

|

Primary Combustion Chamber |

1200Liters(1.2m3) |

|

Internal Dimensions |

120x100x100cm |

|

Secondary Chamber |

600L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Manual |

|

Burner Type |

Italy Brand |

|

Temperature Monitor |

Yes |

|

Temperature Thermometer |

Corundum Probe Tube, 1400℃Rate. |

|

Temperature Protection |

Yes |

|

Automatic Cooling |

Yes |

|

Automatic False Alarm |

Yes |

|

Automatic Protection Operator(APO) |

Yes |

|

Time Setting |

Yes |

|

Progress Display Bar |

3.7 in” LCD Screen |

|

Oil Tank |

200L |

|

Chimney Type |

Stainless Steel 304 |

|

1st. Chamber Temperature |

800℃–1000℃ |

|

2nd. Chamber Temperature |

1000℃-1300℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

7000kg |

|

External Dimensions |

270x170x190cm(Incinerator Main Body) |

|

Burner operation |

Automatic On/Off |

|

Dry Scrubber |

Optional |

|

Wet Scrubber |

Optional |

|

Top Loading Door |

Optional |

|

Asbestos Mercury Material |

None |

|

Heat Heart Technology(HHT) |

Optional |

|

Dual Fuel Type(Oil&Gas) |

Optional |

|

Dual Control Mode(Manual/Automatic) |

Optional |

|

Temperature Record |

Optional |

|

Enhanced Temperature Thermometer |

Optional |

|

Incinerator Operator PPE Kits |

Optional |

|

Backup Spare Parts Kits |

Optional |

|

Mobile Type |

Optional:Containerized/Trailer/Sledge Optional |